Vindhya Telelinks Ltd. (VTL) belongs to the prestigious MP Birla group which is a century old group enjoying excellent market

reputation due to its superior product quality and support to its customers. The group has been pioneer in the field of power and

telecommunication cable industry.

Under the umbrella of M.P. Birla group, VTL has earned an enviable reputation and leadership position in the market and has a satisfied

customer base in domestic market as well as overseas market.

Under the umbrella of M.P. Birla group, VTL has earned an enviable reputation and leadership position in the market and has a satisfied customer base in domestic market as well as overseas market.

In view of increasing demand of E-beam Cables in India, Company has diversified into manufacturing of Electron Beam Crosslinked Cables by establishing a State of the art manufacturing facility situated at Rewa (M.P.). This E-Beam facility is a 3.0 MeV Electron Beam Accelerator along with suitably designed handling systems suitable for irradiation of various types of Electrical & Automotive Cables & Wires, PE Sheets, Polymeric Tubes/ Pipes, Heat Shrink products, Gems & Diamonds, Medical product sterilization. The E-Beam irradiation curing of Elastomer and other polymeric cables has several advantages over conventional steam/dry curing method.

By crosslinking, polymer chains are linked together by so-called cross links. A three-dimensional polymer network is created where the molecules have been joined together into a new non meltable polymer system. Now, the polymer chains loose some of their ability to move as individual chains. The result is no melting.

E-beam technology - Ionizing energy, as provided by an accelerated electron beam (EB), is an efficient means of crosslinking polymers used for wire and cable insulation and jacketing. In this process, the three-dimensional unmeltable network is produced. This can be done without heat. E-beam processing is fast, good, controllable and in a lot of cases more economical than thermal and/or chemical crosslinking.

The electron beam processing in wires and cables helps to improve thermal, chemical, barrier, impact wear and other mechanical properties to meet the demanding applications of the customers in wires and cables.

VTL has installed suitable handling systems to use the facility for following products

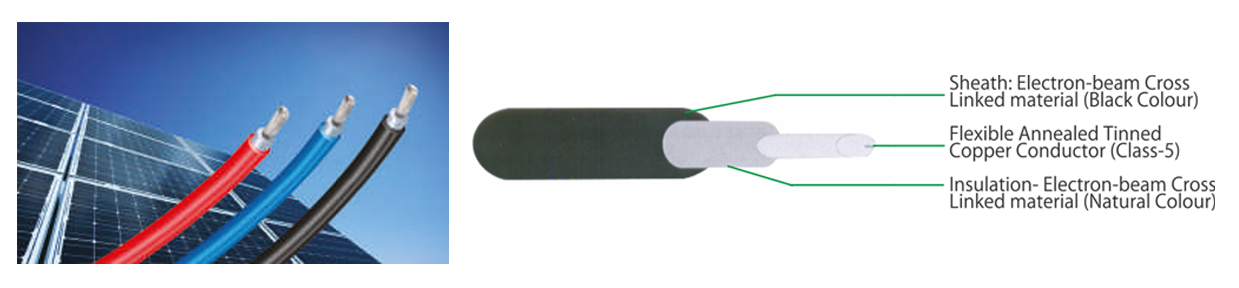

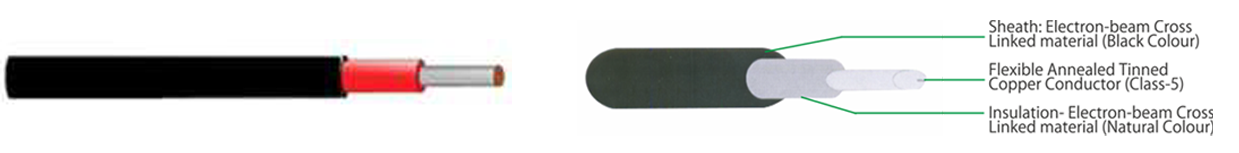

A solar cable is the interconnection cable used in photovoltaic power generation. Solar cables interconnect solar panels, PV cells and other electrical components of a photovoltaic system. Solar cables are designed to be UV resistant and weather resistant. They can be used within a large temperature range and are generally laid outside.

These cables are designed for connecting photovoltaic power supply and can be used in flexible & fixed installations for indoor / outdoor usage with high mechanical strength under extreme weather conditions.

BS EN 50618 - 2014

| Single Core Size(Sq mm) | Wire Diameter Max. (mm) | EBXLInsulation Thickness (mm) | EBXLSheath Thickness( mm ) | Overall Diameter Nominal( mm ) | Conductor Resistance Max. Ohm/Km | Current Carrying Capacity of DC Solar Cable with XL-LOSH Insulation & XL-LOSH Sheathing at 60 Deg. C | ||

| Single Cable in Air (Amp.) | Single Cable on Surface (Amp.) | Two adjacent Cable on Surface (Amp.) | ||||||

| 1.5 Sq mm | 0.26 | 0.7 | 0.8 | 5.4 | 13.7 | 30 | 29 | 24 |

| 2.5 Sq mm | 0.26 | 0.7 | 0.8 | 5.9 | 8.21 | 41 | 39 | 33 |

| 4.0 Sq mm | 0.31 | 0.7 | 0.8 | 6.6 | 5.09 | 55 | 52 | 44 |

| 6.0 Sq mm | 0.31 | 0.7 | 0.8 | 7.4 | 3.39 | 70 | 67 | 57 |

| 10 Sq mm | 0.41 | 0.7 | 0.8 | 8.8 | 1.95 | 98 | 93 | 79 |

| 16 Sq mm | 0.41 | 0.7 | 0.9 | 10.1 | 1.24 | 132 | 125 | 107 |

| 25 Sq mm | 0.41 | 0.9 | 1 | 12.5 | 0.795 | 176 | 167 | 142 |

| 35 Sq mm | 0.41 | 0.9 | 1.1 | 14 | 0.565 | 218 | 207 | 176 |

| 50 Sq mm | 0.51 | 1 | 1.2 | 16.3 | 0.393 | 276 | 262 | 221 |

| 70 Sq mm | 0.51 | 1.1 | 1.2 | 18.7 | 0.277 | 347 | 330 | 278 |

| 95 Sq mm | 0.51 | 1.1 | 1.3 | 20.8 | 0.21 | 416 | 395 | 333 |

| 120 Sq mm | 0.51 | 1.2 | 1.3 | 22.8 | 0.164 | 488 | 464 | 390 |

| 150 Sq mm | 0.51 | 1.4 | 1.4 | 25.5 | 0.132 | 566 | 538 | 453 |

| 185 Sq mm | 0.51 | 1.6 | 1.6 | 28.5 | 0.108 | 644 | 618 | 515 |

| 240 Sq mm | 0.51 | 1.7 | 1.7 | 32.1 | 0.0817 | 755 | 736 | 620 |

For control cable upto 750 volts grade with single layer insulation/sheath for Tap changer for Electric Locomotive AC/DC EMU. BG AC EMU & MEMU /Coaching stock as per specification -ELRS/SPEC/ELC/0018 Rev- 4

VTL has been a leading manufacturer of Railway industry cables and offer specific solution for modern railway signaling, Control, Power, Vehicles and related infrastructure. The requirements include high levels of safety, reliability and energy efficiency. VTL has been leader in India for supply of RDSO approved cables for Indian railway. Now, it offer Electron Beam Irradiated Cables using specialty formulated elastomeric compound to Railway Industries. VTL offer 750 V, 600/1000 V & 1800/3000 V Cable for Railway industries with Halogen free, light weight cables for demanding applications in modern rolling stock, where space is at a premium and power requirement is high.

| Table -1 For Single Core cable ‒ Voltage grade 750 V (EBXL ‒ Insulation) | |||||||

| Sr. No. | Core | Nominal Crosssectional Area (Sqmm) | Conductor | Insulation | |||

| Max. wire diameter (mm) | No. of Wires | Resistance (Ohm/Km) Max. at 20ºC | Min. Wall Thickness of Insulation (mm) | Over all Diameter (mm) | |||

| 1 | 1 | 1.5 | 0.26 | 30 | 13.7 | 0.55 | 2.7 ± 0.10 |

| 2 | 1 | 2.5 | 0.26 | 50 | 8.21 | 0.60 | 3.3 ± 0.15 |

| 3 | 1 | 4 | 0.31 | 56 | 5.090 | 0.65 | 3.95 ± 0.15 |

| 4 | 1 | 6 | 0.31 | 84 | 3.390 | 0.70 | 4.5 ± 0.2 |

| 5 | 1 | 10 | 0.41 | 80 | 1.950 | 0.80 | 5.6 ± 0.3 |

| 6 | 1 | 16 | 0.41 | 126 | 1.240 | 0.86 | 7.2 ± 0.3 |

| 7 | 1 | 25 | 0.41 | 198 | 0.795 | 0.96 | 8.6 ± 0.3 |

| 8 | 1 | 35 | 0.41 | 266 | 0.565 | 1.10 | 10 ± 0.3 |

| 9 | 1 | 50 | 0.41 | 385 | 0.393 | 1.20 | 11.9 ± 0.3 |

| 10 | 1 | 70 | 0.51 | 348 | 0.277 | 1.30 | 14.2 ± 0.3 |

| 11 | 1 | 95 | 0.51 | 456 | 0.210 | 1.40 | 15.7 ± 0.30 |

| 12 | 1 | 120 | 0.51 | 589 | 0.164 | 1.50 | 17.7 ± 0.30 |

| 13 | 1 | 150 | 0.51 | 741 | 0.132 | 1.60 | 20.3 ± 0.3 |

For cable above 750 Volts and upto 1.8/3.0 KV (for Tap Changer Electric Locomotive & AC/DC EMU, BG AC EMU & MEMU/Coaching Stock) as per specification ELRS/SPEC/ELC/0019 Rev 4

Flexible single core power cables, designed for minimum cable weight and diameter. These cables meet the requirements of the modern railway industry. They are halogen free, flame retardant, low smoke and have a low toxicity index. Demands for temperature, abrasion, ozone and oil resistance are also easily fulfilled. These cables are used for inside and outside of rolling stock to connect fixed and moving parts in AC and DC applications.

| Table ‒ 2 For Single Core 1800/3000 V (EBXL ‒Insulation & Sheath) | ||||||||

| Sr. No. | Core | Nominal Cross sectional Area (Sqmm) | Conductor | Insulation | Sheath | |||

| Max. wire diameter (mm) | No. of Wires | Resistance (Ohm/Km) Max. at 20ºC | Min. Wall Thickness of Insulation (mm) | Min. Wall Thickness of Sheath (mm) | Over all Diameter (mm) | |||

| 1 | 1 | 1.5 | 0.26 | 30 | 13.7 | 0.30 | 0.40 | 3.2 ± 0.1 |

| 2 | 1 | 2.5 | 0.26 | 50 | 8.21 | 0.30 | 0.40 | 3.7 ± 0.15 |

| 3 | 1 | 4 | 0.31 | 56 | 5.090 | 0.35 | 0.45 | 4.5 ± 0.15 |

| 4 | 1 | 6 | 0.31 | 84 | 3.390 | 0.35 | 0.4 | 5.1 ± 0.15 |

| 5 | 1 | 10 | 0.41 | 80 | 1.950 | 0.40 | 0.5 | 6.3 ± 0.2 |

| 6 | 1 | 16 | 0.41 | 126 | 1.240 | 0.50 | 0.7 | 8.3 ± 0.2 |

| 7 | 1 | 25 | 0.41 | 198 | 0.795 | 0.60 | 0.8 | 10.2 ± 0.3 |

| 8 | 1 | 35 | 0.41 | 266 | 0.565 | 0.65 | 0.85 | 11.7 ± 0.3 |

| 9 | 1 | 50 | 0.41 | 385 | 0.393 | 0.70 | 0.9 | 13.6 ± 0.3 |

| 10 | 1 | 70 | 0.51 | 348 | 0.277 | 0.75 | 0.95 | 15.6 ± 0.3 |

| 11 | 1 | 95 | 0.51 | 468 | 0.210 | 0.85 | 1.05 | 17.3 ± 0.3 |

| 12 | 1 | 120 | 0.51 | 589 | 0.164 | 0.95 | 1.15 | 19.6 ± 0.3 |

| 13 | 1 | 150 | 0.51 | 741 | 0.132 | 1.00 | 1.2 | 21.9 ± 0.3 |

| 14 | 1 | 185 | 0.51 | 912 | 0.108 | 1.05 | 1.25 | 23.8 ± 0.3 |

| 15 | 1 | 240 | 0.51 | 1184 | 0.0817 | 1.10 | 1.3 | 26.9 ± 0.3 |

| 16 | 1 | 300 | 0.51 | 1480 | 0.0654 | 1.15 | 1.35 | 29.7 ± 0.3 |

Electric cables Thin-wall Insulated, Electron Beam Cross-Linked Irradiated Cable

: EED-50-12(REV 2)

Product Range ‒ 0.5 Sq mm to 630 Sq mm

Product Range ‒ 0.5 Sq mm to 2.5 Sq mm up to 37 Core

Product Range ‒ 0.2 Sq mm to 2.5 Sq mm up to 19 Pair