| Conductor |

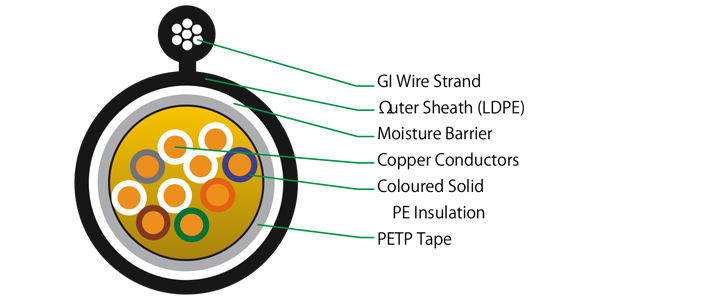

Each conductor consists of a round wire of annealed high conductivity copper. |

| Insulation |

Each conductor is insulated with solid medium/high density polyethylene insulation. |

| Twinning |

Two insulated conductors are twisted with uniform lay to form a pair. The length of the lay of the pairs is so chosen that the cross-talk is minimum. |

| Units & Super Units |

10 or 20 No's of twisted pairs are laid up to form a group which constitutes a unit. Each unit should have an overlapping for color ID. In case of cables

having more than 100 pairs, 5 units of 10 pairs or 20 pairs are laid up to constitute 50 or 100 pairs of super units respectively. |

| Stranding |

For cable upto 20 pairs the required number of twisted pairs are stranded to form a cable core. For cables having 50 and 100 pairs, 5 numbers of 10

pair or 20 pair units are stranded to form 50 and 100 pair cables respectively. For cables having higher than 100 pairs, required number of super units are stranded to form a cable core. |

| Core Wrapping & Screening |

The cable core is wrapped with at least one helical or longitudional plastic tape. Thereafter one aluminium tape ,coated with co-polymer on both

sides is applied longitudinally over the cable core with a specified overlap. The tape is sealed and bonded to the inner surface of the polythene sheath. |

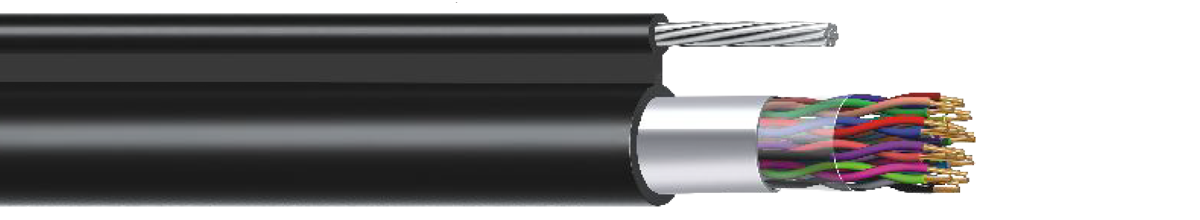

| Suspension Wire / Strand |

A Suspension Wire / Strand is provided. |

| Sheathing |

The screened cable core along with suspension wire as an integral part with the cable is sheathed with black polythene compound to form figure-8 |