| Conductor Diameter | Conductor Resistance at 20ºC | Attenuation at 20ºC |

| 0.90mm | 28 (Each Core) Ω/Km (Max) 56 (loop) Ω/Km (Max) |

4.40 dB/Km (Max. Avg.) at 150KHz 2 dB/Km (Max. Avg.)at 300-3400 Hz |

| 1.4mm | 11.6 (Each Core) Ω/Km (Max) 23.2 (loop) Ω/Km (Max) |

0.3 dB/Km (Max. Avg.) at 0.8KHz 0.8 dB/Km (Max. Avg.) at 5KHz 1.3 dB/Km (Max. Avg.) at 21KHz 2.5 dB/Km (Max. Avg.) at 150KHz |

| Mutual Capacitance | Capacitance Unbalance (800 Hz to 1000 Hz) | |

| 50 ± 2.5 nF/ Km (avg.) | Pair to Pair | Pair to Earth |

| 50 ±6 nF/Km (individual) | 300 pF/Km (max.) | 1500 pF/Km (max. avg.) |

Insulation Resistance 5000 mega Ωs / Km (min.)

| 0.90 mm | ELFEXT : 150 KHz 55 dB/Km Ind. (Min.) 67.8 dB/Km (RMS) (Min.) | NEXT : 55 dB (min.) at 150 KHz |

| 1.4 mm | ELFEXT : at 0.8KHz, 5KHz 21 KHz & 150 KHz 60.0 dB/Km Ind. (Min.) 70.8 dB/Km (RMS) (Min.) | NEXT : 55 dB (min.) at 0.8 KHz, 5 KHz, 21 KHz & 150 KHz |

Reduction Factor ( Field intensity of 50v to 450v) : 0.10 (Max) Characteristic Impedance (Ω)

| 0.90 mm | 470 +/- 15% Ω at 0.8KHz 195 +/- 15% Ω at 5.0 KHz |

| 1.4 mm | 310 +/- 15% Ω at 0.8KHz 150 +/- 15% Ω at 5.0 KHz 110 +/- 15% Ω at 21.0 KHz 100 +/- 15% Ω at 150.0 KHz |

| No1 - White, Orange, Red , Green | No2 - White, Blue, Red , Green |

| No3 - White, Brown, Red , Green | No4 - White, Green, Red , Green |

| No5 - White, Yellow, Red , Green | No6 - White, Black, Red , Green |

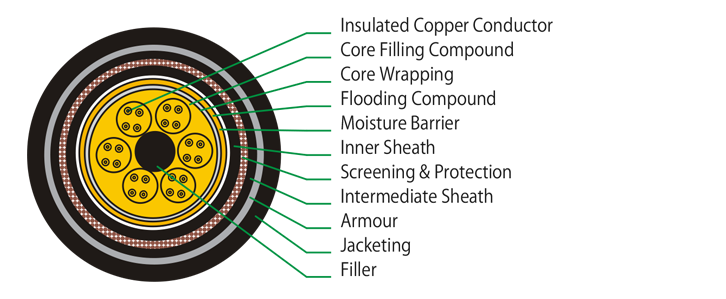

| Conductor | Round wire of annealed high conductivity copper |

| Insulation | Each conductor is insulated with solid PE |

| Quadding | Four insulated conductors stranded to form a star quad. |

| Laying Up | The quads are assembled to form a symmetrical core with a right hand lay. Polyethylene strings of required diameter may be used as fillers, if necessary. |

| Filling & core wrapping | The cable core is fully filled with water -resistant compound and wrapped with polyethylene. |

| Moisture Barrier | Aluminium tape coated with co-polymer on both sides is applied longitudinally over the cable core with a specified overlap. |

| Sheathing | The screened cable core is sheathed with black polythene compound as per BS:6234. |

| Screening & protection | The cable core with inner sheath is surrounded by a reasonably close fitted screen of Aluminium in the form of wires/ strips . The aluminium screen is wrapped with a single layer of woven tape impregnated with Barium chromate with overlap. |

| Intermediate sheath | Further protection of screening is provided by extruded PVC/PE sheath over screening. |

| Armouring | Armouring with two applications of Galvanized steel tape each applied helically with a specified gap. |

| Jacketing | The armoured cable is finally jacketed with black PVC/PE compound. |