| Conductor |

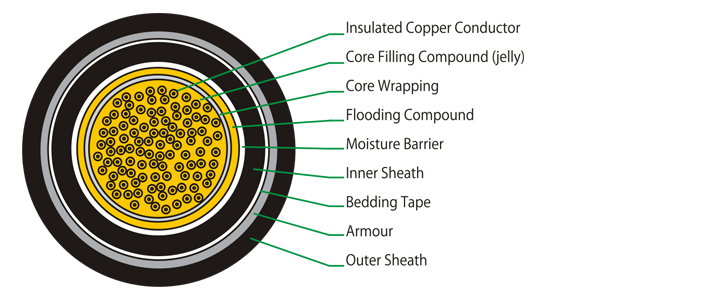

Conductor - Each conductor consists of a round wire of annealed high conductivity copper. |

| Insulation |

Each conductor is insulated with Foam Skin / Solid PE insulation. Foam Skin insulation consists of an extruded inner layer of uncoloured foam,

covered by an extruded outer layer of coloured skin with required colours to meet the specification. For Solid insulation each conductor is insulated with Solid medium/high density polyethylene insulation. |

| Twinning |

Two insulated conductors are twisted with uniform lay to form a pair. The length of the lay of the pairs is so choses that the cross talk is minimum. |

| Units & Super Units |

No's of twisted pairs are laid up to form a group which constitutes a unit. |

| Stranding |

Twisted pairs/ super units are stranded to form a cable core. |

| Filling |

The cable core is fully filled with water resistant compound which is compatible with the polythene insulation of the conductors. |

| Core Wrapping & Screening |

The filled cable core is wrapped with at least one helical or longitudinal plastic tape. Thereafter one aluminium tape, coated with copolymer on both sides is applied longitudinally over the cable core with a specified overlap. |

| Sheathing |

The screened cable core is sheathed with black polythene compound grade 03C as per BS:6234. |

| Bedding tape |

If the cable is required to be armoured, two helical lapping of polythene bedding tape is applied over the polythene sheath. |

| Armouring |

The cable is then armoured with two applications of galvanized steel tape each applied helically

with a specified gap. The second tape covers the gap left by the first tape. |

| Jacketing |

The armoured cable is finally jacketed with black polythene compound grade 03C of BS:6234. |