VTL has setup a new solar power cable plant in the same existing facility of power and telecom cables. The new plant has a state- of-the- art machinery, supplied by the industry leaders. VTL uses raw materials sourced from world renowned suppliers.

As the Solar power is an absolute green & clean form of the energy, the government is giving a lot of emphasis in the growth of solar sector. The Solar cable is one of the most important component in any Solar Power project as it carries the energy generated by the solar cells and transmits to the grid.

These cables are designed for connecting photovoltaic power supply and can be used in flexible & fixed installations for indoor / outdoor usage with high mechanical strength under extreme weather conditions.

BS EN 50618 - 2014

| Cross Section (mm2) (Nom.) | Conductor Construction (Nom No./ Nom dia of wires) (No./ mm) | Conductor dia (mm) (Approx.) | Cable OD (mm) (Approx.) | Conductor Resistance Max. at 20° C (Ohm/Km) | Current carrying capacity at 60° C Amp. |

| 1.5 | 30 / 0.25 | 1.6 | 4.5 | 13.7 | 30 |

| 2.5 | 50 / 0.25 | 2.1 | 5 | 8.21 | 41 |

| 4 | 56 / 0.3 | 2.6 | 5.6 | 5.09 | 55 |

| 6 | 84 / 0.3 | 3.3 | 6.1 | 3.39 | 70 |

| 10 | 80 / 0.4 | 4.3 | 7.1 | 1.95 | 98 |

| 16 | 126 / 0.4 | 5.3 | 8.3 | 1.24 | 132 |

| 25 | 190 / 0.4 | 6.6 | 10.2 | 0.795 | 176 |

| 35 | 266 / 0.4 | 7.9 | 11.6 | 0.565 | 218 |

| 50 | 384 / 0.4 | 9.4 | 13.5 | 0.393 | 276 |

| 70 | 348 / 0.5 | 11.3 | 15.8 | 0.277 | 347 |

| 95 | 460 / 0.5 | 13 | 17.6 | 0.21 | 416 |

| 120 | 585 / 0.5 | 14.9 | 19.4 | 0.164 | 488 |

| 150 | 730 / 0.5 | 16.6 | 21.7 | 0.132 | 566 |

| 185 | 890 / 0.5 | 18.6 | 24.2 | 0.108 | 644 |

| 240 | 1180 / 0.5 | 21.7 | 27.2 | 0.0817 | 775 |

Note: The current carrying capacity is under the situation of laying the single cable in air.

| Rated voltage Uo / U | 0.6/1 kVac & 0.9/1.5 Kvdc |

| Testing voltage | 6.5 kVac for 5 minutes |

| Ambient Temperature | -40°C to +90°C |

| Max Temperature at Conductor | +120°C |

| Service Life | The cable service life is 25 Yrs in Ambient temperature |

| Short Circuit Temperature | 200°C for a period of 5s |

| Bending Radius | ≥4D (D<8mm), ≥6D (D≥8mm) |

| Resistance against acid & alkaline solution |

As per EN 60811-2-1 |

| Cold Bending | As per EN60811-1-4 |

| UV Resistance | HD 605 |

| Ozone Resistant | EN 50396 |

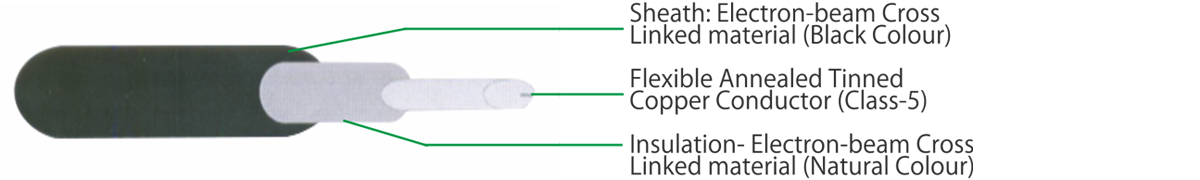

| Conductors | Annealed Tinned Copper (Class 5) | IEC/EN 60228 |

| Insulation | Halogen Free Cross Linked Polyolefin (XLPO) (Natural Colour) | BS EN 50618:2014 |

| Sheath | Halogen Free Cross Linked Polyolefin (XLPO) (Black Colour) | BS EN 50618:2014 |

| Flame Retardant | EN 60332-1-2 | |

| Halogen Free | HCL content < 0.5 % | IEC 60754-1 |

| Low Toxic Gases | (Toxicity Index < 2%) | CEI 20-37 / 4-0 |

| Low Smoke Emission | (Transmitted > 60%) | EN 61034-2 |